Company Profile

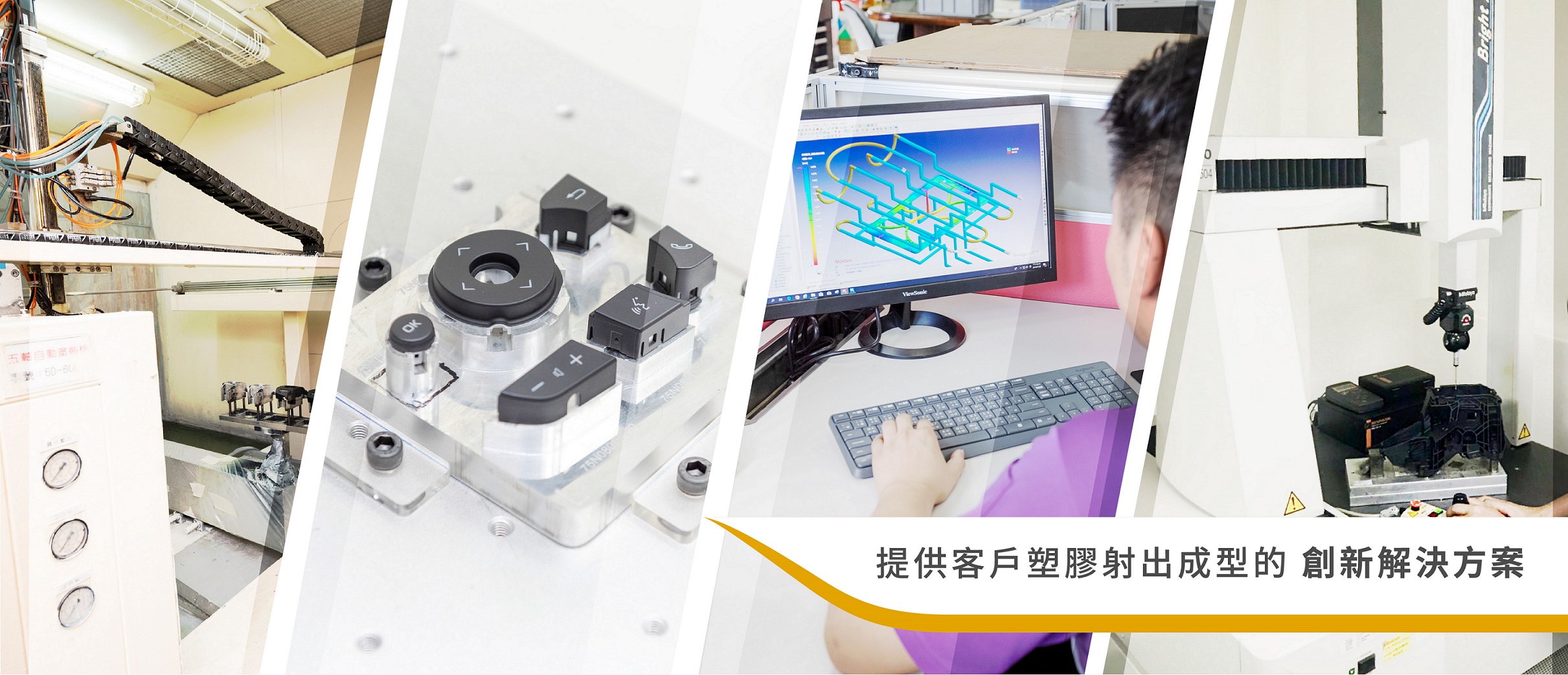

Plastic Injection innovative solutions

Ever Camel Plastic Co., Ltd. was established in 1987 in Taiwan,Professional dedicated to the manufacture of precision molds and injection molding products,Leading the industry for 35 years。

We focus on efficient production services,To provide customers with more cost effective solutions。

Services

Full-service plastic injection

Die Design and Development

Plastic Injection Molding

Professional painting

Assembly processing

Laser engraving

Transport logistics

Die Design and Development

Plastic products production process,Good mold design is the primary key,Because the mold will affect the production quality and yield,Ever Camel Plastic master the most professional mold design and manufacturing technology,Providing customers with complete production planning,And can reduce the risk of、Injection molding enhance the efficiency of。We introduce mold flow analysis system,Gongcheng Bu pre pinpoint the missing products,For the pressure molding process、speed、temperature、Time and location, etc.,Make accurate predictions,To help customers shorten the frequency and duration of test mode,In order to enhance the market competitiveness of products

Plastic Injection Molding

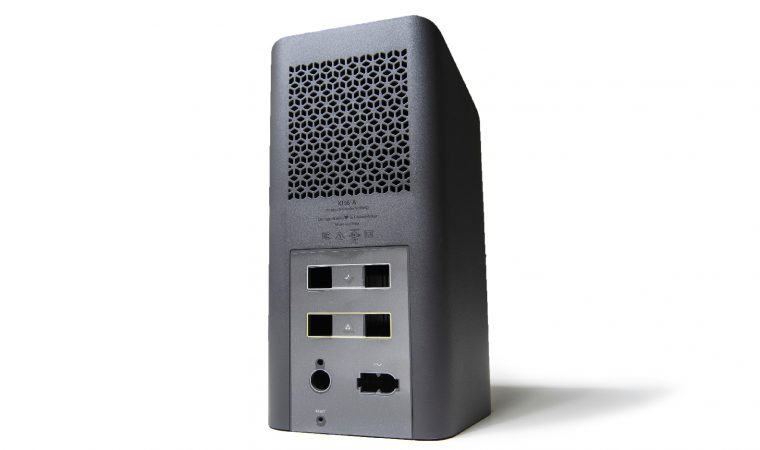

Ever Camel Plastic has extensive experience in plastic products,Possess injection molding machines from 30 to 850 tons,Material can for your needs、Production performance and strength,Product application areas include an optically transparent member、cabinet、Car Accessories、Communications equipment、And living common plastic products。Technical staff will follow the product characteristics and the market can provide an efficient way to process,Ensure product quality excellent,And help you reduce cycle time and cost。

Professional painting

The company has professional spray area,Products for surface treatment,Equipment included:Automatic painting machines to cover the line、Manual spraying line、Printing machine、Automatic / manual printing press、Stamping machine、Ultrasound machines, etc.,FIG jet printing process through professional,The material is more resistant to corrosion、More wear、More heat,Let's extend the lifetime of plastic products,While improving the properties of the surface of the material、Gloss aesthetics,Improve value-added products。

Assembly processing

Ever Camel Plastic has more than 30 years of experience in product assembly OEM,Providing customers with a variety of secondary processing services,Including assembly、printing、Spray painting、Ray carving、Hot Melt、Ultrasonic welding and packaging,To meet the needs of different customers,And through our rigorous testing procedures,Help customers Cengcengbaguan,After the implementation of quality inspection of product assembly

Laser engraving

After painting or plating Ray carving,The text may be part of the pattern or the laser marking to remove paint surface,Color rendering of the original plastic material,Effect may be formed of translucent keys

Transport logistics

Ever Camel Plastic will be completed on schedule we produce products,And arrange for its own truck,Provide customer-specific logistics services,The products reach the customer on time designated place of receipt,Plastic products to become a professional and reliable supplier

Products

For customers to create the highest quality products

Email : service@evercamel.com.tw

Inquiry Now : (03) 352-5390